What do we know about sagittal plane stiffness of AFOs?

Following the recent publication of the paper “Comparison of Sagittal Plane Stiffness of Nonarticulated Pediatric Ankle-Foot Orthoses Designed to be Rigid” by Fatone et al I wanted to share a summary of what the article tells us.

As clinicians prescribing orthoses, the stiffness is vitally important for our prescriptions to achieve their goals. Understanding what we are trying to control allows us to choose materials that will exert an external force onto a person and influence a particular movement pattern.

When prescribing orthoses what do we take into consideration before we can think about material stiffness?

Diagnosis, age, weight, range of motion, muscle tone and what we want the orthosis to do. The materials available to us have evolved over time from traditional leather or metal orthoses to homo and copolymers, silicone, dynamic elastomeric fabrics, carbon composites and now nylons because we can 3D print

The take home points from the paper are:

- All AFOs will deform to some extent under sufficient load

- Rigid AFOs are designed to resist peak plantarflexion and dorsiflexion loads

- Comparison of AFO stiffness between USA and UK manufacturers to establish thresholds for AFO-FC algorithms

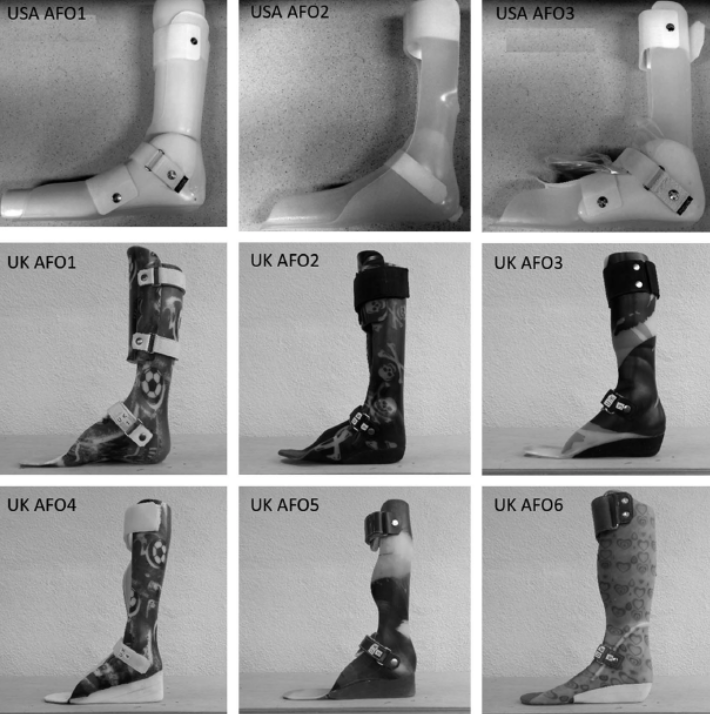

- 9 AFOs were used (image 1). 6 from the UK and 3 from the USA. All made from polypropylene of varying thickness (3-5mm) for patients with cerebral palsy or spina bifida. 2 USA AFOs in design B and 1 design C. UK AFOs 2 represented in all 3 design categories:

- Design A – fixed ankle free MTPJs

- Design B – fixed ankle with fixed MTPJs

- Design C – Fixed ankle, fixed MTPJs and anterior tibial shell

- Various unique design features for each AFO are described in table 1 (see paper)

- Overall UK AFOs were found to be stiffer than the USA AFOs, with comparable stiffnesses in design group B

What does this mean?

This is the baseline data required for creating further evidence about stiffness characteristics of paediatric AFOs. It would be great to see if future papers can tell us about variation in stiffness between different materials and thicknesses.

Additionally, what certain design features like ribs, carbon inserts, trimline design and materials contribute to AFO stiffness and how much. This would allow us to more accurately design our AFO prescriptions. Furthermore, the authors suggest that further investigation into AFO stiffness in other planes at the ankle and at other joints is a logical next step.

What does this mean in relation to 3D Printing?

The clear benefits of 3D printing show us that we can create the same prescription with less weight and less material in much more environmentally friendly way and create more aesthetically acceptable designs. Piro is not just an AFO, but a digital workflow that allows the clinician to be in complete control of the design. The end result is an elegant orthosis.