Where technology meets design

Invest in your practice’s future

It is predicted that one in three custom-made O&P products will be 3D printed by 2027. Ready to be part of the future?

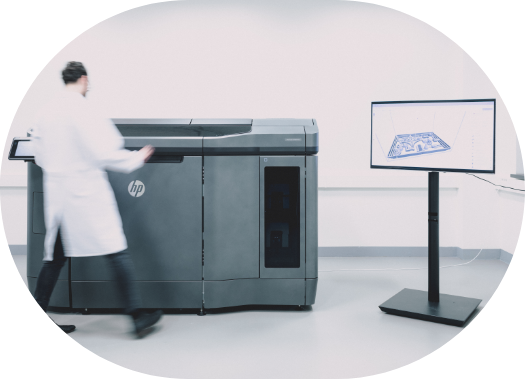

Within traditional orthotic methods, not only is everything done manually, the performance, comfort, look and durability do not always meet patient expectations. However, 3D scanning and printing, and innovative design possibilities truly exceed the limits of the standard manufacturing process. Collaborating with Invent Medical, 3D Ortho is the only UK partner and licensed distributor of 3D scanning and printing.

The 3D process

3D Scanning

Instead of creating a cast, you can use an iPhone, iPad or scanner, to get the perfect fit for your patient. Using our 3D scanning technology, you can scan a patient, cast or plaster model within minutes, giving you measurements on a sub-millimetre level to achieve perfect optimisation and control over the mechanical properties.

Configuration

Alone, 3D scanning is just a tool. Together with advanced design possibilities, it allows you to create products that you never could before. Within an interactive configurator app, you can use advanced algorithms to create, modify and align a 100% bespoke orthosis with your patient. This gives them the fit, comfort and performance to improve their condition, as well as the look and function they desire.

3D Printing

Because of the automated process to scan and design orthoses, printing turnaround times are a lot shorter than traditional methods, meaning you will be able to guarantee your patient’s orthosis will arrive within two weeks. The printing process takes around 24 hours and is then cooled for the same length of time. Once cool, excess powder is removed, and is then dyed or painted to how your patient wants it. The high quality, eco-friendly orthotic materials also use up to 95% less waste, which is better for the planet and your carbon footprint.

Fit

With 3D print orthotics, there is less assembly needed, which means products arrive to fit the patient perfectly, with less need for adjustments. This can half your processing time – saving you hours and costs, and transforming how your clinic works.

Award-winning and accredited orthotics

Transform how your practice works

Discover a more efficient, accurate process when your practice invests in 3D scanning and printing, which lets you create a 100% custom-fit orthosis for a patient in minutes. Get in touch today to find out more about partnering with us.